There are currently no items in your basket

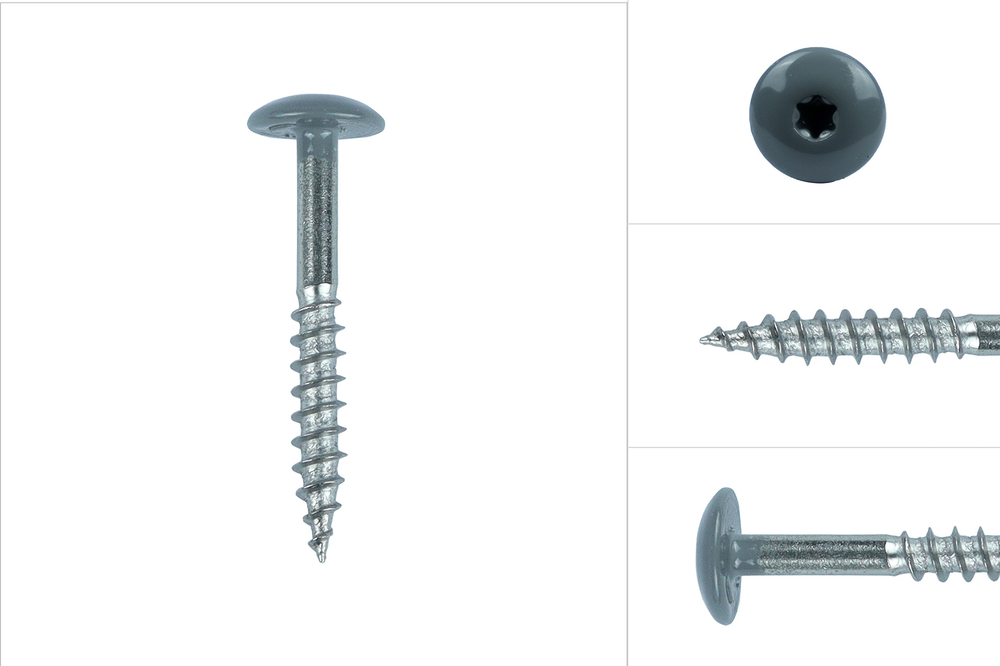

Coloured-head screws Grey Stainless steel 4.8 x 32 mm - Box 100 Pieces

Why choose Coloured-head screws Grey Stainless steel 4.8 x 32 mm - Box 100 Pieces?

- Scratch and UV-resistant Qualicoat coating

- Rustproof even near the coast thanks to A4 quality

- Very large clamping range thanks to wide head

- Easy assembly thanks to torx drive and bits provided

Product details

| Brand | Wovar |

|---|---|

| SKU | WV011472 |

| EAN code | 8720647825928 |

| Colour | Grey |

| Feature 1 | Wide head a 12 mm |

| Feature 2 | Scratch and UV-resistant coating |

| Feature 3 | Coating meets Qualicoat requirements |

| Type | Coloured-head screws |

| Thread | Partial Thread |

| Material | A4 stainless steel |

| Thickness | 4.80 mm |

| Treatment | Colour coating |

| Dimensions | 4.8 x 32 |

| Drive head | TX20 |

| Head Shape | Disc head |

| Milling ribs | No |

| Head diameter | 12 mm |

| Number of screws in box | 100 |

Coloured-head screws Grey Stainless steel 4.8 x 32 mm - Box 100 Pieces

When you want to get started installing various facade panels, such as the well-known Trespa panels, HPL panels or perhaps facade panels, you have 2 choices. Namely, you can choose to glue these panels, which has the disadvantage that in case of a strong storm or under humid conditions, the panels will come loose. There is also a chance that the glue will dry up and crumble over time. For this reason, Trespa screws have been invented. As the name suggests, these screws have been specially developed for mounting facade panels, such as Trespa panels, among others. Coloured-head screws feature a wide head, giving the screws a high clamping range. This ensures a very solid fastening of your wall cladding.

Characteristics of response-head screws

The range of Coloured-head screws offered by Wovar, popularly known as HPL screws, is available in various colours and lengths. Popular variants include Black White, or Grey. The head of the HPL screws features a so-called Qualicoat coating. This special coating preserves the beautiful deep colour of the screw head. In addition, the coating is scratch- and UV-resistant. Popular lengths include the 25 and 38 mm versions. For all colours and lengths, go to our complete range of coloured-head screws.

The head of the screw has a Torx-20 drive. As an added bonus, we supply this bit for free, so you can get started right away! The trespa screws are made of A4 stainless steel. The big advantage of this, compared to A2 stainless steel, is that A4 stainless steel is more resistant to moisture, acids, salts and chlorine. This means you can also use this screw with confidence in a coastal area.

Installing facade panels easily

When installing Trespa and other panels, you should always pre-drill the panel. Do this with a carbide HSS drill bit, which you can find in our range of hardwood drill bits. We recommend pre-drilling the central hole (also called the fixation point) with the 5 mm variant. This drill is just wide enough for our Coloured-head screws. You drill the fixation point centrally at each beam to which the board will be Securing, regardless of whether you are using 2, 3 or more beams. Then pre-drill the other holes (with which you secure the panel to the beam) with an 8 mm hardwood drill bit. This allows the panels to 'work'. This is the expansion and shrinking of the panel due to temperature changes. Drill these holes every 40 cm. Keep in mind when drilling that these holes should be a maximum of 10x the panel thickness (in mm) from the edge of the panel for optimal fastening.

Followed by choosing the right screws.

We advise first of all to look at the RAL colour of your Trespa panel, to get a perfect colour match with the screw you want to use. Then determine the desired screw length, which depends on the panel thickness. Below is a brief overview of the various (standard) plate thicknesses and the suitable screws:

| Sheet thickness | Minimum screw length |

| 6 mm | 25, 32, 38, 50 & 60 mm |

| 8 mm | 32, 38, 50 & 60 mm |

| 10 mm | 38, 50 & 60 mm |

| 13 mm | 38, 50 & 60 mm |

Now you can start installing the boards. We recommend you start by installing the plate at the fixing points. This has the advantage that the plate can easily be 'shifted' if the other drill holes are not perfectly aligned with those of the plate. Then tighten it. Be careful not to tighten it too much, just 'hand-tight' is tight enough (as the plate will expand and shrink). Then start tightening the other screws until all screws are in and the plate is firmly in place. Note, here again, that 'hand-tight' is sufficient in view of the working of the board.

Order Coloured-head screws online

Order this high quality Coloured-head screw today at a very affordable price. Our screws are made entirely of A4 stainless steel (with A2 stainless steel being the standard) and have a scratch-resistant and UV-resistant Qualicoat coating. As a result, you not only receive the best screw on the market at a very affordable price, but also have the assurance that the screws will last for many years!

Is this HPL screw not quite what you are looking for? Then take a look at our entire range of Coloured-head screws, where we have various other sizes and colours at our disposal. For wooden cladding, on the other hand, we recommend our cladding screws. Thanks to the lens head, these screws provide a virtually invisible fastening.